HT ACM: HIGH TEMPERATURE – NO ISSUE, IT WILL GET A LITTLE HOTTER!

For over a decade, Noxtite HT-ACMs covered the gap of material classes up to 150°C (300°F) and beyond 200°C (390°F)

Increased demands on seals and gaskets as well as air-charged engine hoses require polymer materials which can – consistently – withstand 150°C (300°F) and more, and do it at a reasonable material cost. Most Unimatec HT-ACM grades (based on carboxy cure sites) meet these requirements. The diamine cured Noxtite ACMs are pioneer materials in many applications and technologies. These grades match tough automotive specifications with service temperature requirements of -40°C (-40°F) to +185°C (365°F), with short term spikes even up to 200°C (390°F).

The table below provides an overview of our HT-ACM range for seals and gaskets. If you think these don’t match your requirements, please contact us!

HT-ACM Portfolio

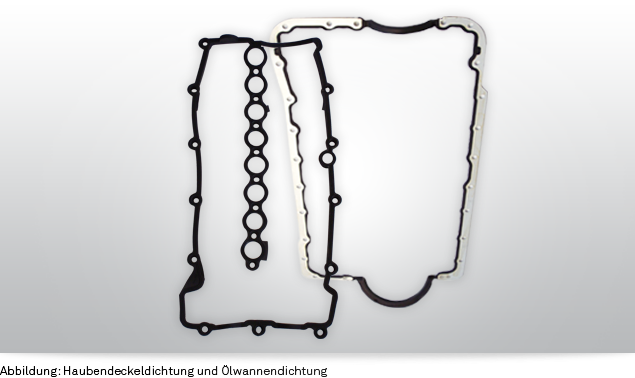

Thinking of demanding hose applications, you will find our HT-ACM grades in air-charged hoses, oil-cooler and EGR lines, and also in injected molded hoses. Modern cars rely on these materials in continuous operation, a look under the hood of the vehicle tells all– or visit our “virtual motor” in our Homepage. Enclosed you find a few of these materials listed:

PA 522HF und PA 526

Compounder advantages at a glance when using NOXTITE® HT-ACM polymers:

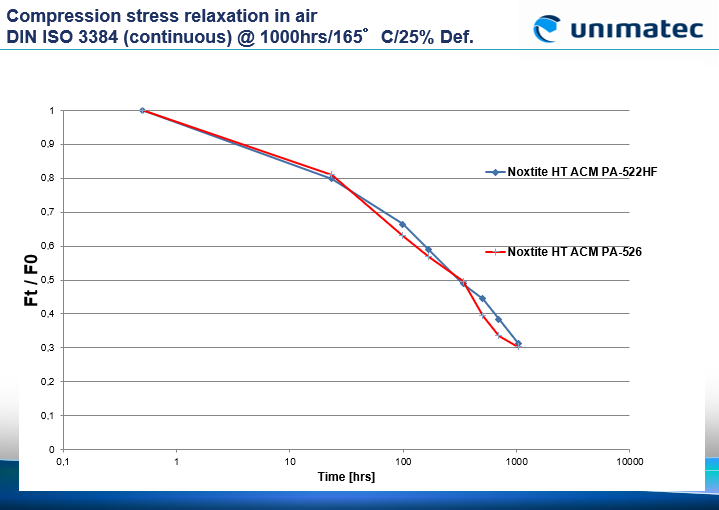

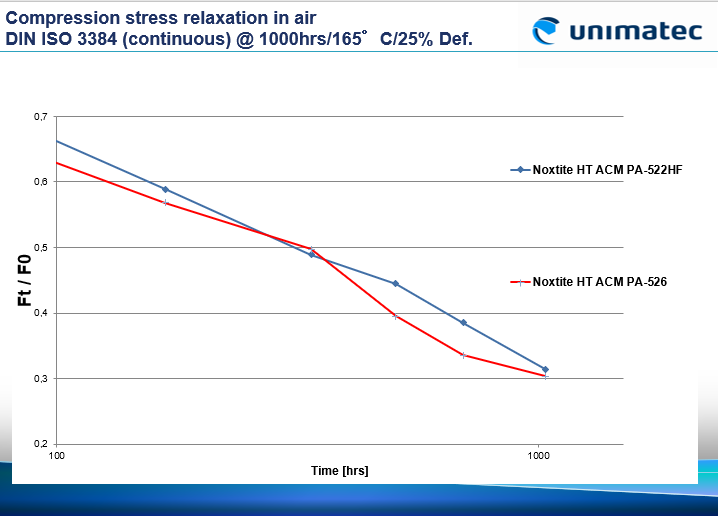

- superior relaxation behaviour and excellent compression set

- significantly improved part life compared to other / standard ACMs

- Enhanced service temperature range of -40°C (-40°F) to +185°C (365°F)

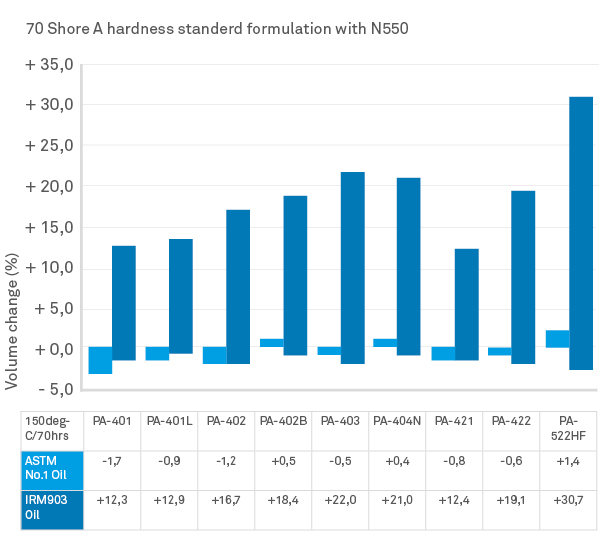

- Improved resistance against modern engine and gearbox oils

- Low temperature performance (-40°C) while maintaining very good oil resistance

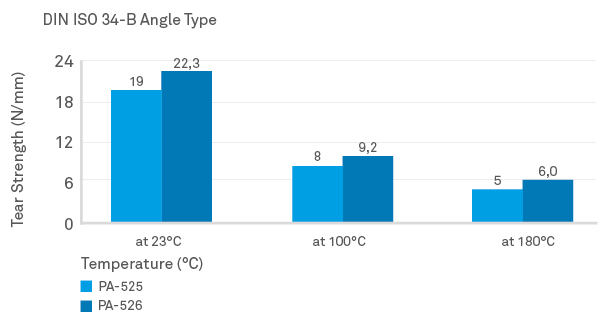

TEAR RESISTANCE

Heat Resistance – DIN 53508

Tear Strength – Angle Type

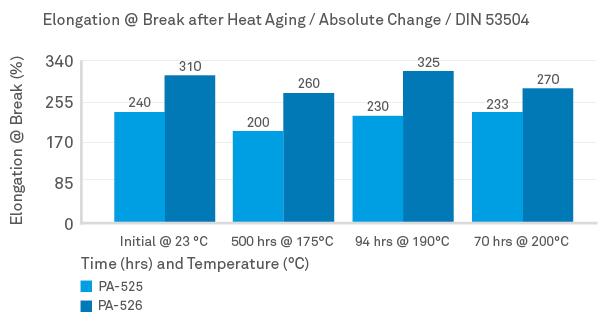

Heat Resistance – DIN 53508

Elongation @ Break

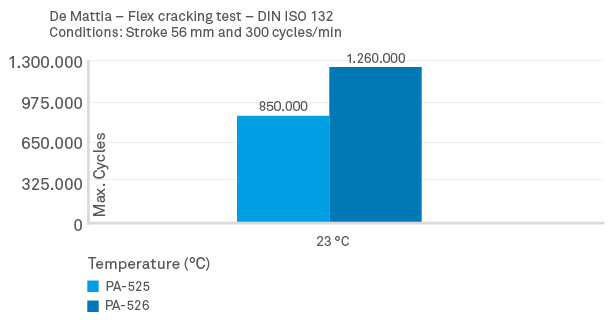

Fatigue Resistance

De Mattia Flex Cracking Test

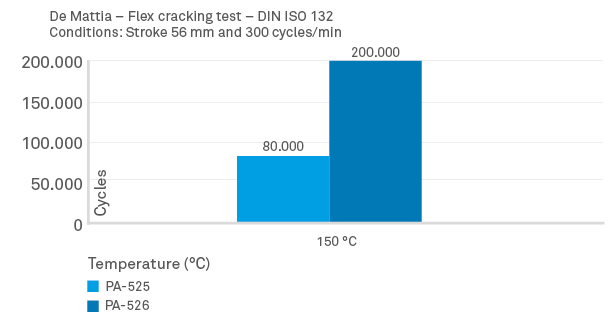

Fatigue Resistance

De Mattia Flex Cracking Test

MINERAL OIL RESISTANCE

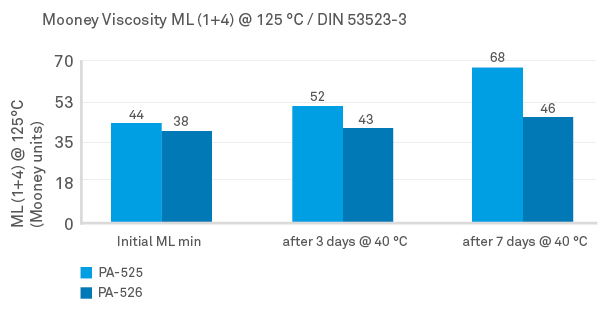

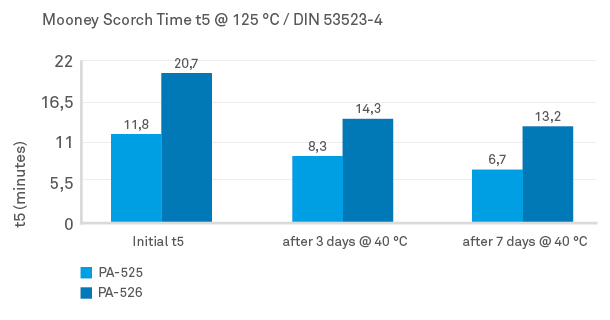

SCORCH

Shelf life stability and Processing Safety

Mooney Viscosity

Shelf life stability and Processing Safety

Mooney Scorch Time t5 @ 125 °C

COMPRESSIVE STRESS RELAXATION